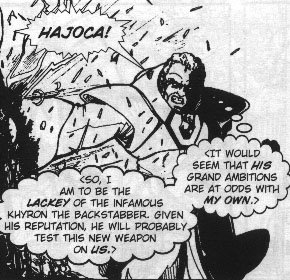

Fun Fact: A character from the 1985 Robotech Comic series yells, “HAJOCA!” However, I do not think he was referring to our company…

February was a pretty exciting month. As I mentioned at the end of January’s post, I spent a week at the Charlotte Pipe and Foundry Company. All of the other management trainees from Hajoca were in attendance as well. There were many familiar faces that I had met at the Managers’ Seminar back in September and there were plenty of new ones too. The new people I hadn’t met yet were the trainees from the Texas and Louisiana region. It was great to finally get to know them.

The trainers at Charlotte had so much to offer. Not only did we learn about Charlotte products specifically, but we were also taught a lot of general industry history and knowledge as well. In addition to facility tours and classroom training, we also spent plenty of time doing hands on work as well. We cut cast iron pipe and built a DWV (drain-waste-vent) system in a mock house using no-hub couplings. We also worked with CPVC plastic pipe and solvents to build a water supply system. Having done this type of work under the supervision of experts, I feel more confident and qualified in being able to help our customers select the right products. It’s one thing to know what something does, but it’s a totally different experience to actually get hands-on training.

Of course I won’t forget to mention that we were provided some very delicious meals and had fun times going out in the city at night.

Coming back to Lansdale was a bit tough because I missed hanging out with the other trainees and the warm North Carolina weather. But things were really picking up at the branch, so I kept pretty busy. A week later, I attended the region’s Counters Plus meeting. This was a day-long meeting organized by the regional manager. Many of the counter salesmen and purchasers were there. The main topic of the meeting was… counter sales! Specifically, the two focuses were increasing sales volume and gross profit margins. We all shared our goals for 2013 and stories about what worked and what didn’t in 2012. There were a couple of vendor representatives there to present and suggest some new items for us to stock and display at our counters.

Jeff says that I will be starting my operations phase of my training next month. This will involve a lot of different things including purchasing, inventory management, accounts payables/receivables (billing), employee records, verifying paperwork, and any other logistics pertaining to running a profit center. Sounds like a whole lot of work, but I’m ready for it. This is what I signed up for when I accepted the opportunity to become a manager!

Dinner after the forecast meeting was a nice opportunity to relax and chat with other managers in a casual environment.

It’s been pretty cold this month, and the weather forecasts indicate that there is a whole lot more cold to come.

Speaking of forecasts, we had our Northeast Region forecast meeting earlier this month. It was a two day conference consisting of group sessions on various topics and issues as well as a private meeting for each profit center manager to discuss his or her 2012 performance and 2013 goals with Rick, Hajoca’s president, and Chris, the vice president. Paul was also there to provide input and feedback as the regional manager.

Jeff and I prepared our packet with our 2012 financial figures as well as our forecasted goals for 2013. We also presented our intangible or non-quantifiable goals such as employee training or personal health and wellness. Rick said he was happy with Lansdale’s performance and wished Jeff another successful year. Everything went smoothly!

Later in the month, I went to a meat packing plant with one of our outside salesmen to do a VMI (vendor-manged inventory). VMI is a business model in which a buyer (in this case, the meat facility) provides certain information to a vendor or supplier (Hajoca) of one or multiple products and the supplier takes full responsibility for maintaining an agreed inventory of the material.

I found VMI to be a neat concept. Although it requires some time and labor from the supplier’s salesperson, this “cost” is offset by the fact that the buyer is relying on the particular supplier for most, if not all, of their purchases. From the buyer’s perspective, they save time because they don’t need to have purchasing agents to monitor inventory levels and write purchase orders ever time they need to restock.

February should be quite an adventure. I’m scheduled to fly to the Charlotte Pipe and Foundry Company for the first week, and our region is having a “Counters Plus” meeting in the middle of the month. Details to come next month!

It feels good to finally get the hang of things at the counter. I feel as though I have good knowledge about our inventory and can help customers get the things that they need. I do notice that we are missing some stuff that I feel that we should have, and my project is supposed to help with this.

In order to track data for lost sales due to stock outages, I have been working with Johnny, our Eclipse systems administrator. I can honestly say that I am incredibly thankful and impressed with Johnny’s assistance. He has activated a new module for our profit center and has even created a report so that I can print out the collected data or export it to an Excel spreadsheet.

Johnny’s willingness to help is not an exception, but rather the norm at Hajoca. All of our support staff in various departments such as accounting, credit, systems, and benefits are excellent resources and always available. I learn so much from them and am ever so grateful.

Finally, Jeff and I are starting preparations for our annual regional forecast meeting coming up next month. This is a review of our profit center’s 2012 performance as well as goals for 2013.

This month, I started doing some work at the counter. Getting to greet and help the customers has been very fun. However, it does get a bit frustrating sometimes to try to find an item in the Eclipse computer system. There are many different codes to enter for different products, and I am doing my best to try to learn them all. Fortunately, the Hajoca veterans here have all been very helpful.

I decided for my project that I would work on tracking lost sales and increasing purchasing and inventory levels for certain items which would result in an increase in net revenues and profits. The concept is complete, and I have spoken with the sales and purchasing personnel abut it. The most challenging aspect will be to gather the necessary data. My regional manager, Paul, believes that there is a way to track lost sales resulting from stock outages in Eclipse. I am working on this with the Eclipse system administrator and hope to have all the details ironed out in a few weeks.

Finally, I had the opportunity to go on a business trip to Marshalltown, Iowa. Hajoca recently opened a new branch in Marshalltown, so several people went there to help them move the profit center into a new building and take inventory. We had Hajoca personnel from Arizona, Florida, Virginia, Colorado, and Pennsylvania (yours truly) fly to Iowa and make this move happen. We spent a week over there working long days, but the learning experience was priceless (and the overtime pay was nice too!). I would definitely volunteer for any other opportunities like this in the future.

One thing I noticed about most of the business project presentations last month was that they focused heavily on increasing total sales or gross profit margins. While I do understand that sales is the bread and butter of any type of business (especially in wholesale and distribution), I want to attack the other side of the coin.

I set up meetings with Sam, our purchasing agent, as well as John and Bernie who are buyers at other Hajoca branches. From them, I learned a lot about how we buy and each purchaser had his own little tricks and ways of doing things. I had worked a few different sales or sales related jobs in the past, but this was the first time I was getting direct exposure to the purchasing side of business. I think a common misconception is that buying is “easier” than selling. While the act of simply buying might be easier than selling something, it isn’t easy to buy well (i.e. obtain the best price, purchase optimal quantities, identify which items to stock, etc.)

Overall, the three meetings were quite eye-opening. I think I may have a pretty good idea of what I want to do with this information. I’ll write more about this next month, when I have a more concrete plan. And I would really like to thank Sam, John, and Bernie for all of their help.

Otherwise, everything is going well in the warehouse. I have a firm grasp of how things operate and I am ready to progress onto counter sales next month. Apparently the challenge of counter sales will be product knowledge as you’re often put on the spot to come up with a part or solution for the customer’s needs.